September 22, 2021

Building A Circular Economy

By Alan Cuddihy, VP of Sustainability at PCH International

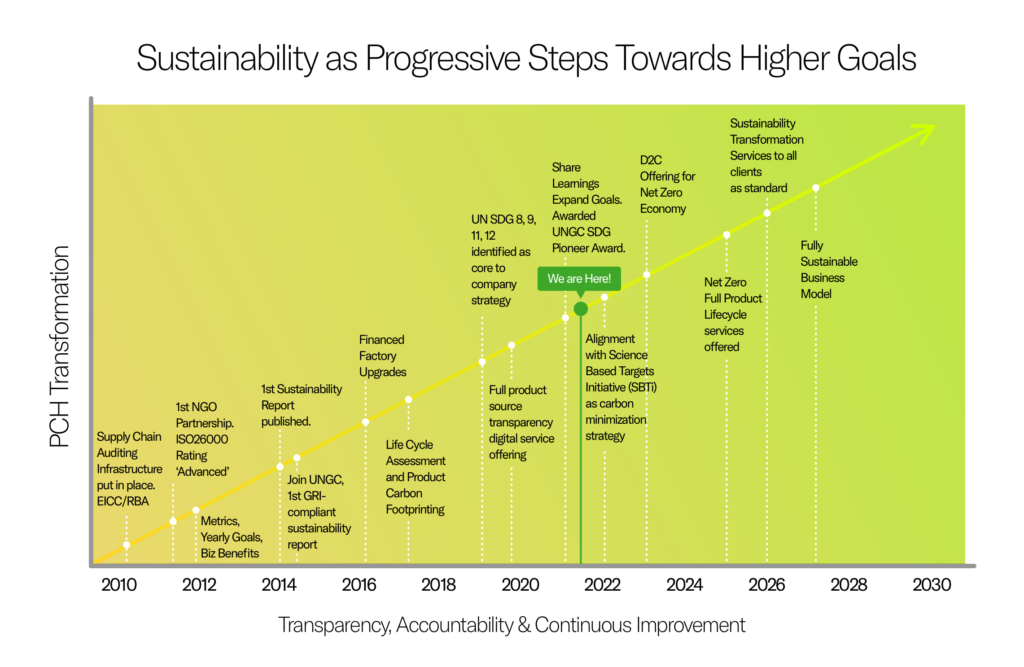

In June of this year, I was honored to be named one of ten United Nations Global Compact (UNGC) SDG Pioneers. PCH was also recognized for our work to promote a Circular Economy by advancing more efficient, flexible, transparent, and sustainable supply chains.

In the spirit of the UNGC — which recognizes that sustainability depends on collaboration from businesses across industries and geographies — there’s value in sharing a few of the things we’ve learned on our sustainability journey. We hope that PCH’s story can help other businesses take positive strides toward a more sustainable future.

1. Implement metrics to set the foundation for sustainability

Since our inception in 1996, we have been deeply committed to sustainability — it’s better for business and is the right thing to do. The steps we’ve taken to positively impact our workforce set the foundation for our sustainability journey. In the early 2000s, we visited third-party factories and encountered poor working conditions for workers. We saw opportunities to help these workers, but we were not able to unilaterally enact improvements. PCH does not own manufacturing capacity, so we had to work to influence our suppliers by suggesting practical and constructive changes. For these suggestions to stick, we worked to educate suppliers about best practices and showed how improvements would benefit them — resulting in better productivity from employees and helping them win contracts from international brands.

For example, in August 2012 we engaged the China-based, grassroots NGO Little Bird to better understand workplace-related grievances and educate workers about their rights. Through this partnership, we helped implement libraries, chat lines, and drop-in centers where workers could pursue training, exercise, social activities as well as talk one-on-one with Little Bird representatives. We tracked grievances (as well as time to resolution) and worker satisfaction. Within a few years, we were able to demonstrate a five-to-one return on investments in the form of productivity and retention.

2. Embrace public disclosure and transparency

After joining the UNGC in 2012, we published our first comprehensive, GRI-compliant sustainability report in 2013, demonstrating our commitment to sustainable progress.

Making the leap to voluntary public disclosure was a pivotal step in our sustainability journey, as it allowed us to track and measure against public-facing sustainability goals related to people, products, and supplier metrics.

As a result, we can more easily demonstrate the benefits of sustainability to all of our stakeholders. Since then, we have published a yearly sustainability report in adherence to the Global Report Initiative (GRI). And, most importantly, this disclosure has given us latitude to further our investment in sustainability over the years.

3. Move upstream to increase your impact

At the outset, PCH’s sustainability efforts focused on the immediate impacts of our supply chains — ensuring worker health and safety (both in our own operations and those within our supplier network) and improving the environmental impact of operations (taking harmful chemicals and conflict materials out of the supply chain, reducing waste, and enhancing energy and water efficiency). However, once we had established a firm baseline, we began to look for ways to move sustainability into earlier stages of our business.

Because we work at the early product development phase, we saw an opportunity to engage industrial designers to consider sustainability issues early in the product concept and design phase. Design decisions such as materials, finishes, and color have large implications on the sustainability of a supply chain. For many years, we have worked hand-in-hand with designers to help educate them about the relationship between product concept, industrial design and supply chain impacts. The product journey begins during the design phase, and this is where product circularity (and even end of life impacts) can best be addressed.

For example, we have focused on the sustainability of product packaging as an avenue for enhancing the sustainability of the supply chain. As one might expect, we seek to reduce the size of packaging and implement compostable, recyclable, biodegradable, or reusable materials whenever possible. But it’s also important to account for logistical and business considerations in designing packaging — creating modular packaging systems with limited shapes and sizes that fit the entire product family and can be palletized efficiently. This methodology increases efficiency, decreases shipping, handling and storage costs, and reduces environmental impacts such as material, fuel, and electricity use, helping brands improve supply chain sustainability performance.

4. Build a sustainable business model

With the foundation for sustainability in place, we turned our attention to look at the very core of our business — our business model.

Sustainable Development Goal 12 calls for more responsible consumption and production. One of the biggest sources of waste is overproduction caused by the lack of supply chain visibility and flexibility. Oftentimes, this overproduction is a result of massive, unresponsive forecast-driven supply chains.

As we’ve written in the past, D2C supply chains offer a better, more sustainable alternative. Having access to real-time, end-to-end data, can help minimize waste caused by overproduction. This entails moving away from capacity-led supply chains towards consumer-driven demand chains that entail less product being built for inventory and storage. Today, we are working to fundamentally shift our entire business toward a more responsive, sustainable D2C model. The goal should be to develop a product life cycle that is chosen because it delivers on design, user experience, cost, quality, and speed — and also happens to be verifiably the most sustainable option.

To make real gains in sustainability, we encourage other companies to examine their business model too. Rest assured, most C-suite executives don’t make business decisions that work against the bottom line — regardless of how “sustainable” they are. By moving upstream and thinking about sustainability at the highest level of business (and armed with performance data), businesses shouldn’t have to choose between profitability and sustainability.