March 29, 2021

Direct-to-Consumer Success Requires Rethinking Your Supply Chain

With waves of retail openings and closings, the uncertain retail landscape will no doubt continue well into 2021 and beyond.

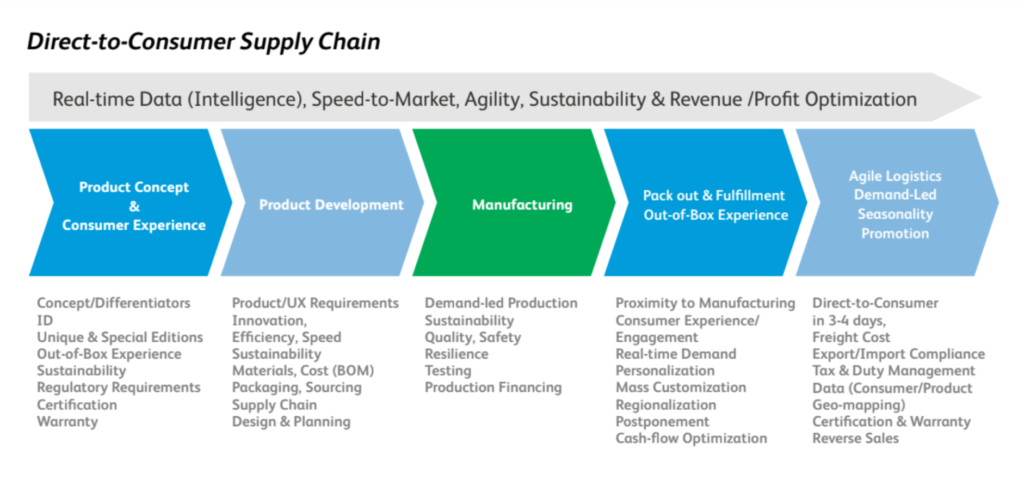

To meet or exceed consumer expectations for speed, unique products and sustainability, I along with our team at PCH, advise major brands that their supporting supply chain must be agile, responsive, resilient, intelligent (real-time data + analytics + actionable levers) and provide even greater economies of scale. We see that brands are increasingly gravitating to the direct-to-consumer (D2C) channel.

From our experience working with top global brands and startups, the D2C model – in which brands develop a direct relationship with their customers – offers clear, long-term benefits, such as:

• Build consumer brand affinity and loyalty

• Gain valuable insight (data – both consumer and operational)

• Provide unique and highly differentiated products, and

• Better manage operations based on real-time consumer demand (versus

retail forecast)

• Reduce over-production as well as minimize inventory and scrappage, which will also help decarbonize supply chains and contribute to sustainability goals

But the challenge is: Do brands require a unique D2C supply chain or will their B2B supply chain work just as well?

Going direct to consumers creates risks beyond marketing products successfully. Brands are keenly aware that they must create consumer awareness, engagement and demand. We advise brands to take a deep

review of their supply chain and optimize their operations for the direct-to-consumer model. Often, D2C requires reconfiguration of the B2B supply chain.

Below are three key supply chain considerations when addressing the D2C opportunity:

1) Retrofitting your existing B2B supply chain:

a. To deliver D2C, it is best to: Relocate postponement and fulfillment operations close to manufacturing. This will reduce the number of required distribution locations and provide considerable savings in inventory and handling costs, while reducing lead times and optimizing availability.

b. Proximity matters and the distribution center (where regionalization, personalization, pack out and fulfillment take place) must be close enough to pull-through production when demand requires, using data directly from your e-commerce eco-system.

c. A single source of inventory maximizes product availability, creating a just-in-time approach to fulfillment. This can be done only with a granular understanding of demand, component lead times, and on-hand inventory. Some contract manufacturers offer D2C capability but be certain they can also deliver the level of branded out-of-box experience your customers

expect.

2) Reconfiguring your supply chain from end-to-end:

a. Ex-factory distribution is very different from direct-to-consumer distribution. Supply chains built to meet the demands of B2B customers are rarely able to adapt to the very different requirements of D2C. Supply chains built to service large bulk orders, or large builds that are delivered to a single, or few locations, won’t support a D2C model. A supply chain overhaul is often needed.

b. The key is to start with the consumer experience and design your supply chain to deliver this experience. If you integrate consumer expectations at the product requirement stage, you can drive unique special edition products and sustainability goals to deliver an engaging consumer experience, as well as capture end-to-end supply chain data that results in efficient inventory management.

c. Another important consideration is configuring your supply chain to deliver single orders at scale (mass customization). To enable ‘last mile’ logistics that deliver your promise, the processes for the 8,000-mile last mile (fulfillment center direct to consumers worldwide) must also be redesigned. Products should be packed out on demand, then shipped quickly and

efficiently to destinations around the world.

d. Consumers increasingly enjoy monitoring progress and so delivery status must be available to consumers (and the brand), digitally and on-demand.

3) Supply chain flexibility, transparency and sustainability:

a. The right supply chain partner will ensure that you have the right products in the right markets at the right time.

b. Supply chains can no longer be black boxes; they must provide visibility, reliability and consistency of service, transparency, and traceability in real-time and with granular, accurate detail.

c. Data is invaluable to brands for operational management, consumer engagement, and sustainability. Supply chains are complex and the ability to react quickly to fluctuating demand and market shifts requires access to accurate data. For this reason, every step of the product journey – from product development (materials, certifications, BOM, packaging, etc.)

through manufacturing (yield, quality, safety, lead times, etc.) to fulfillment (customization, personalization, demand, backlog, forecast, lead times, etc.) to logistics (transportation, freight cost, documentation, last mile, reverse-logistics, etc.) – must capture data that can be accessed and analyzed for business optimization.

d. As consumers become increasingly concerned about environmental impact and the brand they support, transparency is required. The right supply chain partner will provide transparency and adhere to international sustainability standards and guidelines, while optimizing resources, reducing costs and minimizing over production.

e. Success is as much about the right partner as the right strategy.

Today, a more sustainable supply chain is a competitive differentiator – good for the environment, good for all stakeholders, and necessary to achieve positive business metrics.

The ability to deliver direct-to-consumer is key for brands. This channel offers the opportunity to be close to customers, have access to valuable consumer data and realize a variety of operational efficiencies. But it isn’t as simple as making adjustments to the way brands market and sell products. We advise our customers to put in place the right supply chain to realize the full benefits of direct-to-consumer. Selecting the right supply chain partner is a way for brands to act quickly, while they consider whether it is necessary to develop their own direct-to-consumer supply chain capability. Partners must deeply understand the geographies in which they operate, consumer requirements and design their end-to-end processes to adapt their services to changing needs.

Liam Casey is the founder and CEO of PCH International, which works with global companies that are passionate about design, brand and the consumer experience. For 25 years, PCH has worked with the world’s best brands and innovative startups to create and deliver breakthrough products and consumer experiences.

Liam is widely recognized as a thought leader in hardware, supply chain, sustainability, go-to-market strategies, and startup initiatives. He is an entrepreneur known for disrupting traditional supply chain models, spotting trends, and driving innovative solutions that have contributed to the success of many international brands.

PCH provides services from product concept and development, through manufacturing, pack out and delivery direct to consumer. The company is global with large operations in China in Shenzhen’s Futian Free Trade Zone.

As a leader in sustainability, PCH publishes a yearly GRI-compliant sustainability report and is a member of the United Nations Global Reporting on sustainability.

Liam is a member of the Board of Directors of the California College of the Arts, and a member of the Advisory Board for the Jacobs Institute for Design Innovation at the College of Engineering at the University of California Berkeley.

Please contact us: info@pchintl.com