End-to-end Solution

A global non-tech consumer goods company invested billions in a new family of devices. They needed a partner who could take the products from concept to manufacturing to distribution and meet tight deadlines. PCH worked with our customer's design team to develop an array of accessories to support their device rollout, and was able to meet the customer's key requirements of look and feel, functionality, color variety, reliability, sustainability and cost.

The Challenge

This customer was seeking a partner to support the development of a line of accessories for its latest product. Among the leather goods and electrical accessories required were carry cases, charging devices and disposal devices – all of which had to be ready to ship in just eight months. A further challenge stemmed from the fact that the device design was not fully defined, meaning the accessory design was, in turn, subject to change. Finally, responding to consumer trends, the accessories would use new materials and fabrics and the selection of these materials was crucial.

PCH solution

PCH was engaged from the outset, helping define the product concept and develop functional prototypes to iterate and prove the design, ensuring compatibility with the device industrial design reference. Each prototype used a different manufacturing technique and material stack-up, resulting in an optimum outcome for design, cost, sustainability and manufacturability. PCH conducted rigorous testing throughout this phase, including accelerated life testing, environmental impact testing and user testing simulations.

Early collaboration with PCH enabled our customer to identify and overcome design challenges quickly, expediting the development process while protecting the integrity of the accessory design. PCH’s core expertise in accessory development and manufacturing using leather, natural fabrics and synthetic was a key factor in identifying sustainable, non-toxic materials and manufacturing processes.

The result

PCH prides itself on matching our customers’ designs and materials selection by relentlessly pushing the boundaries to replicate these factors into shippable goods. This project was no different: Through extensive prototyping and experimentation, PCH was able to realize our customer’s vision for the accessories in terms of look and feel, functionality, colors, durability, quality, reliability, sustainability and cost.

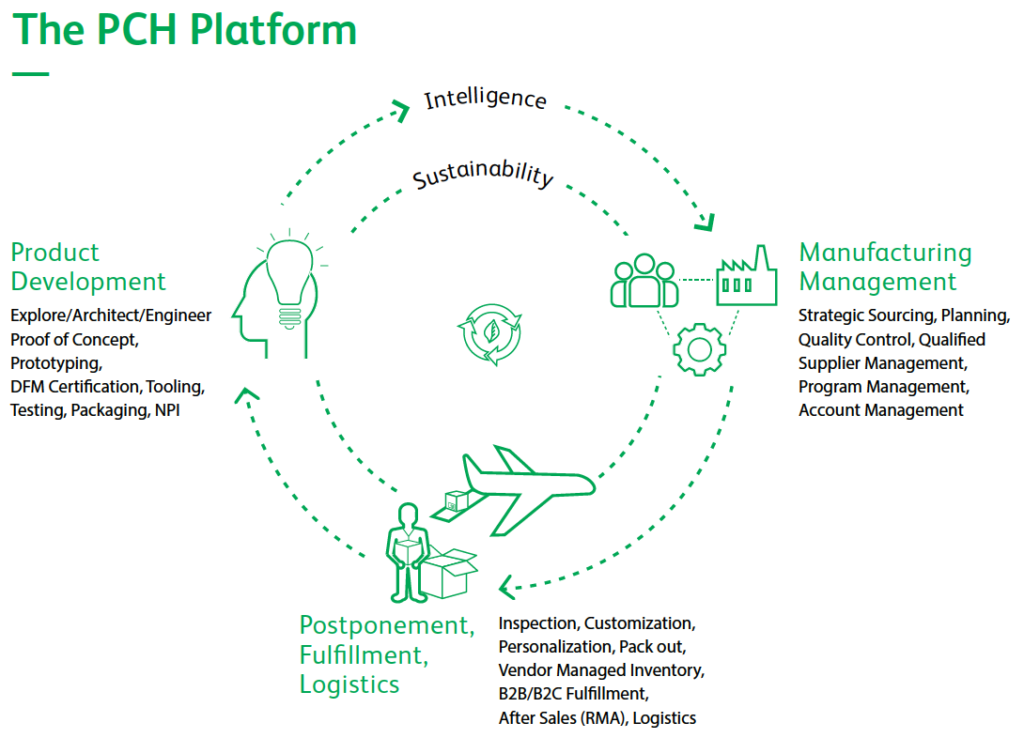

PCH’s diverse expertise and ability to provide an end-to-end solution was key. PCH used its suite of capabilities and supply chain relationships to maximum effect, supporting our client at all stages of the product journey – from initial product concept, to development, to manufacturing and distribution. Working closely with the customer and the design studio, the PCH team continuously adapted the accessory designs based on changes in the corresponding device design.

While keeping design intention at the forefront, PCH optimized for cost, sustainability, manufacturing, and distribution. In addition, PCH adhered to the strict marketing launch deadline and successfully delivered the accessories on time and within budget.